VEDREX delivers sophisticated surface technologies that combine authentic aesthetics with uncompromising performance, offering architects and builders unlimited design possibilities through advanced powder coating and sublimation processes.

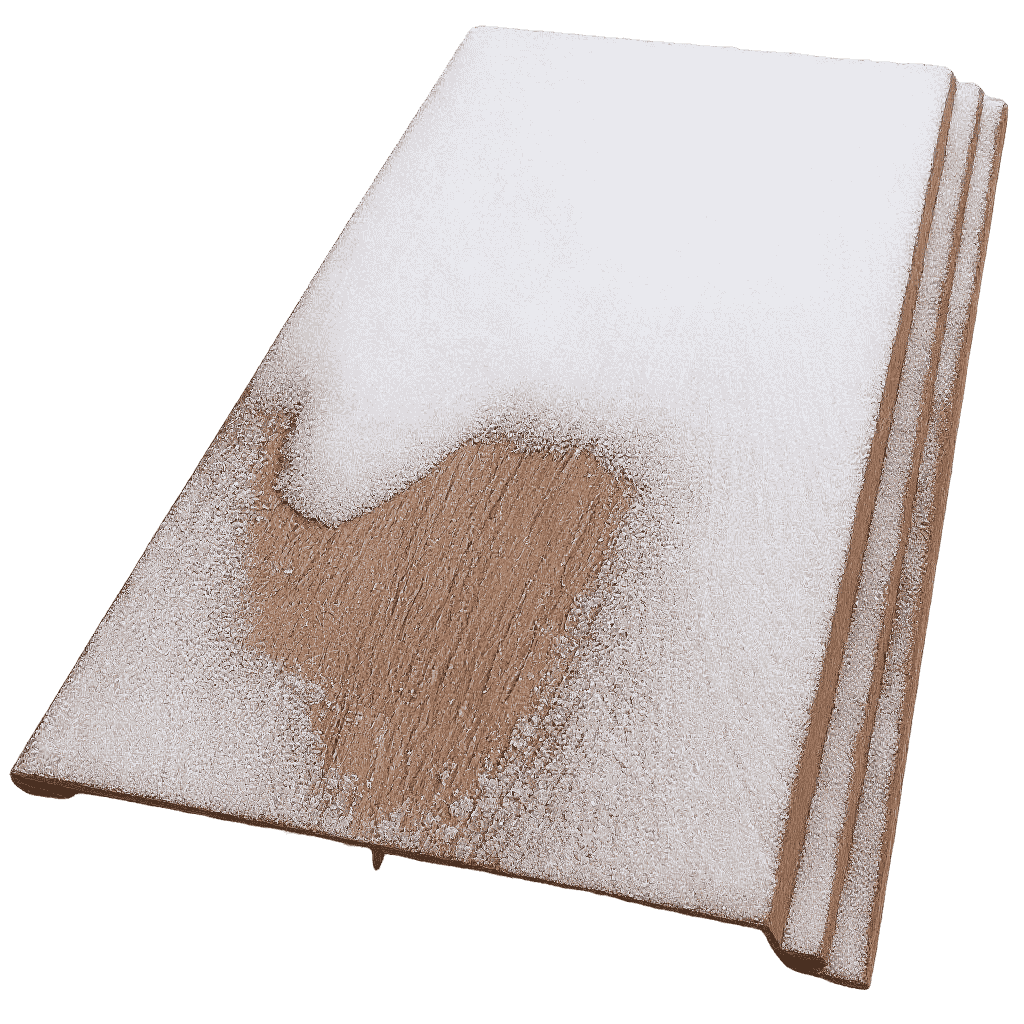

Advanced sublimation technology creates realistic wood textures without maintenance demands

Powder-coated solid colors engineered for fade resistance and long-term durability

All finishes engineered to withstand extreme climates and environmental conditions

Authentic wood aesthetics through advanced sublimation technology that embeds realistic grain patterns directly into aluminum surfaces.

Premium powder-coated colors engineered for maximum UV stability and long-term performance in demanding architectural applications.

Bespoke finish development for unique project requirements, working with architects to achieve specific color and texture goals.

Proven color and texture pairings that create stunning architectural results across residential and commercial applications.

Request material samples to see and feel the superior craftsmanship and authentic finishes that set VEDREX aluminum systems apart from the competition.

No repainting or staining required for decades

Every VEDREX finish undergoes rigorous testing to ensure exceptional durability and long-term aesthetic performance.

Maintains color stability under extreme sun exposure

Performs in freeze-thaw cycles and humidity extremes

Scratch and dent resistant powder-coated surfaces

Common questions about VEDREX finish technologies, performance characteristics, and application guidelines for professionals.

VEDREX finishes are engineered for +20 years of color retention and surface integrity, depending on different weather conditions, backed by comprehensive warranty coverage.

Yes, all VEDREX woodgrain finishes feature corrosion-resistant sublimation technology that prevents delamination and maintains authentic appearance in coastal and humid climates.

Powder coating creates a harder, more durable surface than liquid paint, offering superior scratch resistance, color retention, and environmental protection without VOC emissions.

Yes, VEDREX offers custom color matching services for architectural projects requiring specific brand colors or unique aesthetic requirements.

Our finishes are tested for thermal cycling from -40°F to 180°F, maintaining adhesion and flexibility through repeated freeze-thaw cycles without cracking or peeling.

Minor scratches can be touched up with matching repair pens. For significant damage, individual planks can be replaced while maintaining seamless appearance.

Normal rainfall provides adequate cleaning for most installations. Annual washing with mild detergent maintains optimal appearance in high-pollution or dusty environments.

All VEDREX finishes are engineered for global climate performance. Regional considerations focus on color selection for thermal management rather than durability concerns.

AAMA 2604 and 2605, Qualicoat Class II and III, DIN EN ISO 9227:1990 standard, ASTM E84