At Vedrex, we offer powder-coated, sublimated, and engineered aluminum solutions that excel in design, durability, and performance.

VEDREX aluminum systems deliver unmatched durability through advanced engineering and premium materials, withstanding extreme weather conditions while requiring zero maintenance. Our architectural-grade aluminum features hidden fastener rainscreen technology for streamlined installation, authentic woodgrain textures that never fade, and non-combustible construction that meets the highest safety standards. As an eco-conscious solution made from recycled aluminum, VEDREX combines unlimited design versatility with sustainable building practices that architects, builders, and contractors demand.

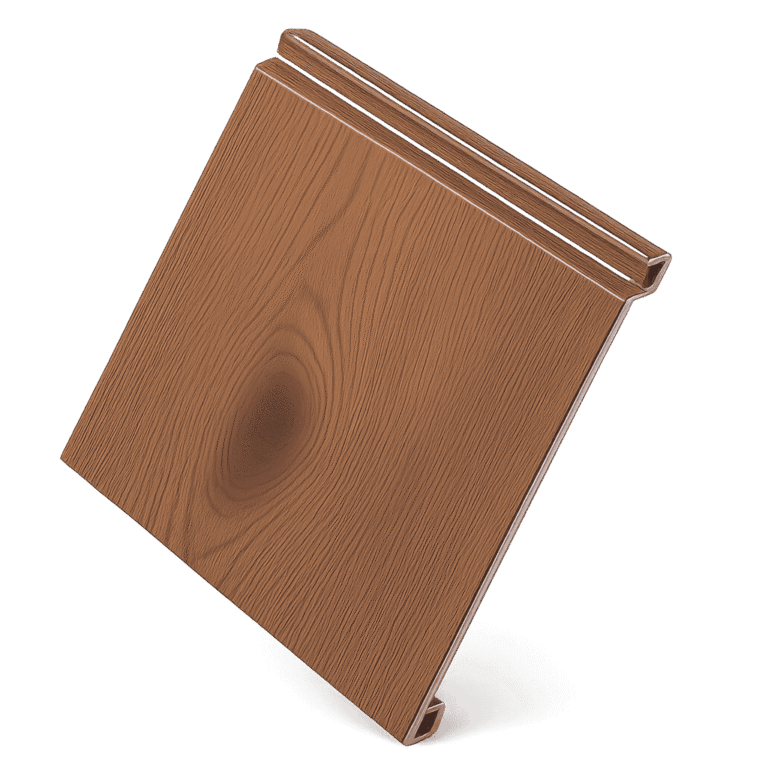

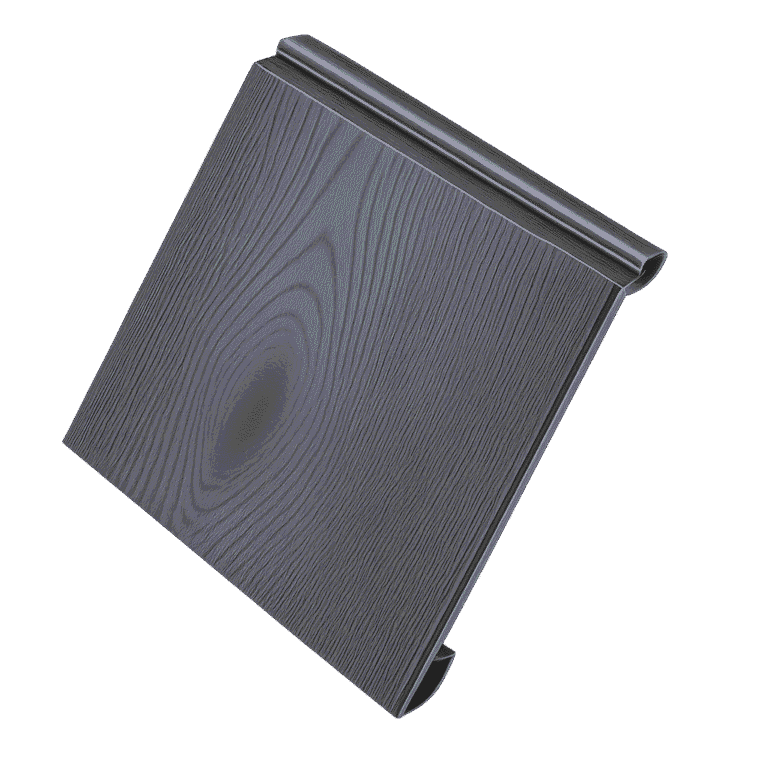

Architectural-grade aluminum siding that delivers lasting protection and striking aesthetics. Engineered for harsh climates with authentic woodgrain and solid color finishes that maintain their beauty for decades.

Versatile aluminum solutions for both ventilation and continuous coverage. Perfect for residential and commercial applications requiring moisture protection and refined finishing.

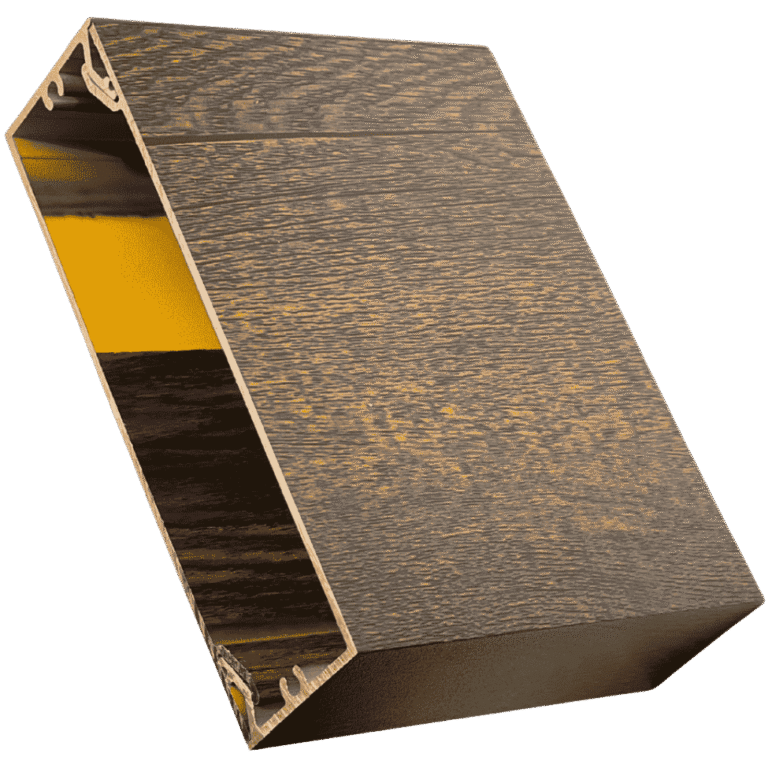

Precision-engineered aluminum components for limitless design possibilities. From pergolas to privacy walls, these versatile systems bring modern sophistication to any interior or exterior project.

Architectural-grade aluminum siding that delivers lasting protection and striking aesthetics. Engineered for harsh climates with authentic woodgrain and solid color finishes that maintain their beauty for decades.

Versatile aluminum solutions for both ventilation and continuous coverage. Perfect for residential and commercial applications requiring moisture protection and refined finishing.

Precision-engineered aluminum components for limitless design possibilities. From pergolas to privacy walls, these versatile systems bring modern sophistication to any interior or exterior project.

See how VEDREX aluminum cladding systems deliver exceptional results across diverse architectural applications and environments. These projects highlight our commitment to sustainability, cost-effectiveness, and customer satisfaction in the building exterior sector.

Request material samples to see and feel the superior craftsmanship and authentic finishes that set VEDREX aluminum cladding systems apart from the competition.

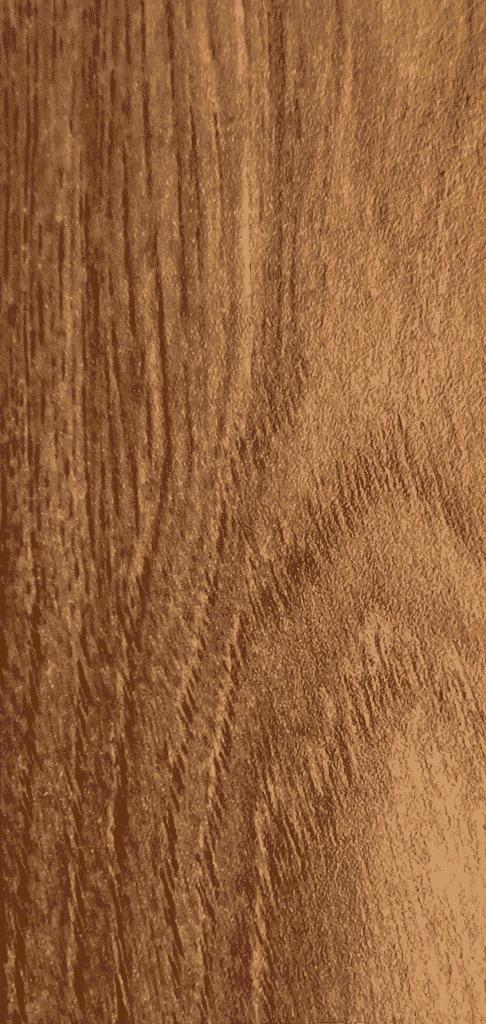

VEDREX offers an extensive range of premium surface finishes engineered to elevate any architectural project, featuring authentic woodgrain textures created through advanced sublimation technology and vibrant powder-coated solid colors that deliver both natural warmth and contemporary boldness while maintaining superior durability, UV resistance, and long-term performance without fading, chipping, or requiring maintenance.

Access comprehensive documentation, technical resources, and expert guidance to support the design, specification, installation, and long-term care of VEDREX aluminum cladding systems.

Discover the performance advantages, sustainability benefits, and cost-effectiveness that make aluminum the superior choice for modern construction projects.

Step-by-step installation guides and system details to support contractors, installers, and specifiers with efficient, code-compliant setup procedures.

Simple care recommendations and maintenance schedules to preserve finish longevity and keep VEDREX surfaces looking their best for years to come.

Find detailed specifications, CAD drawings, performance data sheets, and compliance documentation to simplify design, quoting, and project approval processes.

VEDREX aluminum cladding systems allowed us to achieve the authentic wood aesthetic our client demanded while meeting our strict performance requirements. The sublimation technology delivers incredibly realistic woodgrain textures that rival genuine timber, but with the durability and fire resistance essential for commercial applications.

Principal Architect, Urban Design Collective

After 20 years in construction, I can confidently say VEDREX delivers on every promise. The installation process is straightforward with their hidden fastener system, the material quality is exceptional, and most importantly—zero callbacks. My clients love the authentic woodgrain appearance, and I love that it’s maintenance-free. When you’re building premium projects, material failures aren’t an option. VEDREX gives me the confidence to guarantee my work and focus on craftsmanship instead of worrying about product performance.

Owner, Rodri Build